Long-term extension of meat reduction piping with 'Composite Repair' *Presentation of construction case materials

Repairs are made according to the necessary durability years and purpose (strength restoration, leak prevention, corrosion protection). It allows for predicting maintenance timing and is suitable for permanent plant maintenance!

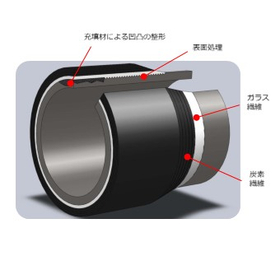

"Composite Repair" is a preventive maintenance measure for reduced-thickness piping that complies with the international standard ISO 24817. Through strength calculations, the optimal repair range and number of layers are determined based on the required service life and purpose. High-quality materials with a maximum design life of 20 years are used, and construction is carried out under thorough management. By repairing with composite "before penetration," the service life can be predicted, thereby avoiding the risk of unexpected equipment shutdowns due to pipe breaks caused by external corrosion. This not only reduces production losses from leaks at penetration points but also facilitates long-term equipment renewal planning after repairs. 【Strengths of Composite Repair】 ■ Design can be tailored to purposes such as strength restoration, leak prevention, and corrosion protection (strength calculations) ■ Preventive maintenance measure for reduced-thickness piping with predictable service life ■ Strength restoration and leak prevention possible with a maximum design life of 20 years ■ Design and construction compliant with ISO 24817 ■ Quality that has passed performance tests by third-party organizations *You can view case studies of construction in thermal power plants and oil refining plants, as well as proposal materials tailored to the purpose of repairs, from the "PDF Download" section. Please feel free to contact us with any inquiries.

- Company:富士ファーマナイト

- Price:Other